The implementation of fast clamping tools provides multiple strengths in contemporary sheet metal fabrication:

Back again GAUGES are precision positioning equipment very important for precise sheet metal placement in press brake functions. These numerically controlled reference factors guide the operator in positioning the workpiece versus the die.

I am consistently imagining, examining, and composing about these topics, frequently striving to stay at the forefront of my industry. Enable my understanding and experience be an asset to your online business.

Price tag-Effectiveness: By cutting down non-productive time and labor costs linked to lengthy tool improvements, speedy clamping systems lead to overall operational effectiveness.

Enhanced Flexibility: Fast tool variations allow manufacturers to handle a various number of bending operations and tiny batch dimensions far more properly.

These technological developments have created press brakes increasingly appealing to producing corporations throughout numerous sectors, from automotive and aerospace to HVAC and buyer electronics.

Then again, bottoming features better precision which is favored when tight tolerances are required. Roll bending is usually utilized for producing big-radius curves, such as from the manufacturing of cylindrical parts. Therefore, the ideal bending process relies on the material’s meant use and the precise condition necessary.

In order to develop significant-high quality machined parts which has a smooth visual appearance, it’s essential to take into consideration some crucial variables linked to CNC machining.

The again pressure assembly, built to be non-leaking Discover According to the customer’s necessity, contains a reversing seat valve and two aid valves.

To be a mechanical engineering pro with yrs of knowledge, I’ll get rid of light-weight within the evolution of this crucial metalworking machine and its essential part in shaping the globe all around us. Get ready to find out the secrets at the rear of the press brake!

Minimized Set up Time: Operators can swiftly switch between different punch profiles without having intensive downtime, making it possible for For additional economical production scheduling.

The entrance help arms of the press brake are integral parts affixed for the T-groove or linear guideline positioned on the machine’s front face. These arms characteristic a manually adjustable again position claw, improving versatility and precision in sheet metal dealing with.

The incoming AC voltage is processed through the internal system transformer, which then outputs the suitable voltages for a variety of subsystems.

By giving true-time angular measurements, goniometers help operators to realize exact and regular bends in sheet metal fabrication.

Angus T. Jones Then & Now!

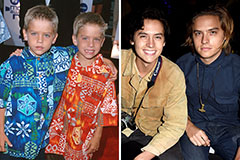

Angus T. Jones Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!