The work spindle or major and counter spindle of a lathe has a lathe chuck wherein the raw product is held. The velocity and therefore the resulting torque depends on the machining method.

In contrast, a normal lathe demands guide Procedure, in which the machinist manually guides the slicing tool. CNC lathes offer you higher precision, a lot quicker generation, and the ability to make extra complex parts when compared to guide lathes.

The CNC lathe headstock transmits power with the motor towards the workpiece, enabling exact rotation and motion for machining. It securely grips the workpiece and makes it possible for variable speeds, facilitating the development of intricate designs.

The basic principle of turning has not adjusted Considering that the vintage lathe: A workpiece is rotated by way of the principle spindle in addition to a cutting movement is created via Make contact with with a turning tool.

All of our quality lathes are meant to the highest high quality requirements. The increased rigidity of The brand new JAP benches minimizes the affect of vibrations for the duration of machining.

Advanced CNC lathe headstocks may perhaps contain features for example compelled spray lubrication systems to cut back friction and heat technology, and automatic tool changers to enhance productiveness.

Bar feeders automate the feeding of bar stock into your lathe, making it possible for for continual Procedure. This is critical for high-volume generation.

The machine tool field’s most person-pleasant control is much better than ever, and able to make it easier to develop Virtually anything.

Star sliding head technologies can match numerous milled and turned parts as many as a greatest diameter of 42mm, and our machines is usually configured for making miniature prismatic parts or shafts in excess of 2m. Great things about sliding head technologies

This short article was prepared by engineers in the BOYI group. Fuquan Chen is a professional engineer and specialized qualified with twenty years of encounter in speedy prototyping, mildew manufacturing, and plastic injection molding.

By securely gripping the workpiece and rotating it at different speeds and directions, the headstock facilitates the generation of intricate shapes, contours, and features with precision and repeatability.

Positioning accuracy refers to how near a CNC lathe might get into the supposed posture. Envision telling your Mate to face specifically 5 toes away.

The headstock also contains the Explore bearings that assistance the spindle. High-precision bearings reduce vibrations and strengthen rotational accuracy, which happens to be important for making high-top quality parts.

These lathes are perfect for creating round parts. The bar stock is fed through the collet along the Z-axis, plus a stationary tool cuts the rotating bar stock. This setup is good for easy, symmetrical parts like rods and shafts.

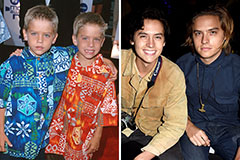

Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now! Catherine Bach Then & Now!

Catherine Bach Then & Now!